#Pareto analysis

Explore tagged Tumblr posts

Text

Analyze Phase of DMAIC in Lean Six Sigma

Introduction In continuous improvement, the Lean Six Sigma methodology is a proven approach for reducing waste, increasing efficiency, and driving business success. At the heart of Lean Six Sigma lies the DMAIC framework, a structured process for solving complex problems. DMAIC stands for Define, Measure, Analyze, Improve, and Control. In this blog post, we will focus on the Analyze phase, where…

View On WordPress

#Analyze phase#DMAIC#Fishbone diagram#five whys#hypothesis testing#Lean Six Sigma#Pareto analysis#Regression Analysis#Root Cause analysis

1 note

·

View note

Text

an inconvenient curmudgeon

WHEN YOU’RE SICK OF JORDAN PETERSON BUT HE KEEPS TALKING IN YOUR HEAD

-- Yes, IQ is a bell curve; almost half of everybody really are more or less headblind. (IQ Distribution Studies)

-- Yes, men run in packs, yes, they stupidly follow heedless braggarts. (Male Hierarchies)

-- Yes, 20% succeed while 80% mill around in mediocrity. (The Pareto Principle)

-- Yes, Disagreeability is a genetically-linked trait that won’t just go away. This is an euphemism for pig-headedness, arrogance, blind aggression and vindictiveness. (Five-Factor Analysis)

WE’RE AT THE TOP OF THE FOOD CHAIN BECAUSE WE’RE THE TOP PREDATOR. WE WISE UP OURSELVES OR WE BLUNDER ON IN DENIAL.

#inconvenient#male hierarchies#IQ#jordan peterson#pareto principle#five-factor analysis#former liberal#arrogance#aggression#stupidity#mediocrity#braggarts#pig-headedness#vindictiveness#food chain#denial

0 notes

Text

What are 7 QC Tools? 7 QC Tools: The Foundation of Quality Management

In the realm of quality management, the 7 Quality Control (QC) tools, also known as the 7 Basic Tools of Quality, serve as the bedrock for analyzing and improving processes. These powerful tools, developed by Dr. Kaoru Ishikawa, are indispensable for identifying issues, making informed decisions, and enhancing overall quality. This article delves into the details of the 7 QC tools, their…

View On WordPress

#7 QC Tools#Business Excellence#Cause-and-Effect Diagrams#Check Sheets#Continuous Improvement#Control Charts#Cost Savings#Customer Satisfaction#data analysis#Data-Driven#Decision Making#Defect Concentration Diagrams#Flowcharts#Healthcare#Histograms#Manufacturing#Operational Excellence#Pareto Charts#Problem Identification#Process Improvement#Process Stability#Quality Control#Quality Management#Root Cause Analysis#Service Sector#Versatile Solutions

0 notes

Text

time management in the ib

good time management is crucial in the ibdp (international baccalaureate diploma programme) due to its demanding workload and diverse requirements. effective time management helps you focus better on your tasks, leading to higher quality work and more efficient use of your time.

by organizing your schedule and prioritizing tasks, you can reduce feelings of being overwhelmed and manage stress more effectively.

good time management also allows you to allocate time for relaxation and social activities, which is essential for maintaining mental and physical health. the ibdp involves numerous assignments, projects, and exams, so managing your time well ensures you meet all deadlines without last-minute rushes.

balancing extra-curricular activities

balancing your ibdp workload with extracurricular activities can be challenging, but it’s definitely achievable with some strategic planning. here are a few tips to help you manage both effectively:

create a schedule: use a planner or digital calendar to map out your week. allocate specific time slots for studying, completing assignments, and participating in extracurricular activities. this helps ensure you dedicate enough time to each area without neglecting any.

prioritize tasks: identify your most important and urgent tasks each day. focus on completing these first before moving on to less critical activities. this way, you can stay on top of your ibdp requirements while still enjoying your extracurriculars.

set realistic goals: break down larger tasks into smaller, manageable steps. set achievable goals for each study session or activity, which can help you stay motivated and avoid feeling overwhelmed.

use downtime wisely: make use of short breaks between classes or activities to review notes, read, or complete small tasks. this means no doom scrolling. at all. these pockets of time can add up and help you stay productive.

communicate with teachers and mentors: let your teachers and extracurricular mentors know about your commitments. they can offer support, provide extensions if needed, and help you manage your workload more effectively.

take care of yourself: ensure you get enough sleep, eat well, and make time for relaxation. maintaining your physical and mental health is crucial for sustaining high performance in both academics and extracurriculars.

be flexible: sometimes, unexpected events or deadlines may arise. be prepared to adjust your schedule as needed and stay adaptable to changes.

practicing time-management techniques

there are several effective time management techniques that can help you stay organized and make the most of your time. here are a few popular ones:

pomodoro technique: work in focused intervals (usually 25 minutes) followed by a short break. this helps maintain concentration and prevent burnout.

time blocking: allocate specific blocks of time for different tasks or activities throughout your day. this ensures you dedicate time to important tasks without interruptions.

eisenhower matrix: prioritize tasks based on their urgency and importance. this helps you focus on what truly matters and avoid getting bogged down by less critical tasks.

pareto analysis (80/20 rule): focus on the 20% of tasks that will produce 80% of the results. or, the most urgent and impactful of the eishenhower matrix. this helps you prioritize high-impact activities.

experiment with these techniques to find which ones work best for you.

still struggling with time management?

if you’re still struggling with time management, don’t worry—it’s a common challenge, especially with a demanding program like the ibdp. here are a few additional steps you can take:

seek support: talk to your teachers, school counselors, or a mentor. they can offer guidance, resources, and strategies tailored to your specific situation.

review and adjust: regularly review your schedule and time management strategies. see what’s working and what isn’t, and make adjustments as needed.

limit distractions: identify and minimize distractions during study time. this might mean turning off notifications, finding a quiet study space, or using apps that block distracting websites (i recommend tracking yourself on ypt).

practice self-compassion: be kind to yourself. it’s okay to have off days or to struggle with time management. recognize your efforts and progress, and don’t be too hard on yourself.

consider professional help: if time management issues are significantly impacting your well-being or academic performance, consider seeking help from a professional, such as a therapist or a coach who specializes in time management.

in summary, mastering time management is crucial for success in both academic and personal areas. with commitment and practice, you can develop strong time management skills that will serve you well throughout your life. keep aiming for balance and don’t hesitate to ask for help when needed. you’ve got this!

❤️ nene

i hope this post helps, @cherrybros

#that girl#becoming that girl#student#productivity#study blog#chaotic academia#it girl#student life#academia#it girl aesthetic#nenelonomh#ibdp#ibdp student#international baccalaureate#balance#time management#productivitytips#procrastination#habits#planning#it girl mentality#pinterest girl#it girl energy#clean girl#study#100 days of studying#study aesthetic#studying#study hard#study inspiration

128 notes

·

View notes

Text

get ready for my thoughts on yaoi UBI

So I’ve kvetched about UBI in the tags for long enough someone finally asked me what I was going on about so here we go!

I will start with some caveats:

I am British, and so I can only speak about the British specifics.

I have for the past twelve years worked as a professional health economist, and health economics is based on social welfare theory (specifically growing out of Arrow’s work in the 1960s and Sen’s work in the 80s/90s). I literally could talk forever about this, but I won’t. If you want to know more, read the pretty good wikipedia article on welfare economics.

But fundamental to welfare economics is two things: if we make a great big change, do the benefits outweigh the costs? And does the change make a fundamental change for good? (aka cost-benefit analysis and pareto efficiency).

The other thing you need to know about me is that I don’t like activists very much, because they never have to show their working, and my entire professional life is showing my working, and critiquing other people’s working. We all have ideas mate, show me the plan! I love a plan! and this isn't coming from anything but personal experience; I have been to talks by UBI activists before, including ones by economists, but I have never had the case made to me that UBI would be either cost-beneficial OR approach pareto efficient. In fact, it usually reminds me of arguments that are based on some other imaginary world, and then I get so annoyed I want to scream.

In the early 2010s when I was first starting working as an economist, I was asked to build a model to see whether switching a disability benefit from government administered to individual administration would be cost-effective. Essentially, if you were newly in a wheelchair and you needed a ramp building up to your house, would it be better for the government to organise a contractor, or for you to be given a cash transfer and organise it yourself? The answer was that it wasn’t, but anyone who has ever had to hire a builder could have told you that, and the government didn’t have to pay my firm £30,000 to make that decision. But that is what UBI essentially is; a cash transfer where you get cash and the government gets to enjoy less responsibility.

There are 37.5 million people of working age in England. (Nearly) every single working person gets what's called a tax free allowance, where the government doesn’t claim income tax on the first £12,570. (Once you make over £120k, your allowance starts to decrease, and you lose it entirely at I think £150k)

Let’s assume that instead of just not claiming tax on this amount, the government switched to making that £12,570 your UBI. That is £471,375,000,000 just for England - just under half a trillion pounds. In cash, or nearest as in our modern economy. And not one off - Every year.

Okay, let's say that the country does have a spare half a trillion a year (in cash) lying around. What is the benefit to switching from tax free allowance to UBI? Well, let's assume that no one stops working, so there would be the tax receipts from the 20% income tax on the £12,570, and that’s just a shade under £100 million. Not bad.

But if you’ve seen a UBI post, you will know that people like the idea because they will be able to work less. Which probably means that UBI will need to be paid for in some other way. Perhaps by cutting existing benefits. The universal credit cost is around £100 billion. So we’re still £300 billion short, and honestly, you wouldn’t cut all of universal credit anyway, probably only the unemployment benefits, but I’m not digging into the maths on that tonight.

But, look, I am sympathetic. I am a welfarist. I genuinely believe that the economy is not just money, that welfare is happiness, it is utility, it is all the stuff that makes life worth living, and it is the responsibility of the government to maximise the welfare/happiness/utility/quality of life of the country through efficient use of taxation and other sources of money. So people give the government money and it spends it on goods and services and then people get utility, and then they spend their own money to get more utility, and ultimately we can gain intangible things that are incredibly valuable.

But the problem is that cash is cash, cold and hard and very real. I don’t know how unlimited spare time translates into half a trillion real pound coins. I wouldn’t know how to build a model that complex and uncertain, especially as this all assumes that you can live on 12k a year, and that whatever replaces progressive taxation is equally progressive. I haven’t even touched on how having a convoluted welfare state insures it somewhat against being entirely destroyed after a change in political opinions, aka what I call the daily mail test. You think the narrative about people on welfare is bad now? But also, how would you deal with people who didn’t manage their UBI money well? What happens if there is a personal crisis?

The more I look at it, the more the existing system is actually remarkably good value for money. Individualism is expensive. Collective decision making and spending is just cheaper.

Ultimately I don’t see the additional benefit of UBI, requiring a pie in the sky change, when it is far, far, far more cost effective to strengthen the existing regime across the board; taxation law, social safety net, childcare, working laws, education and health - all systems that are already in place, and have a thousand times higher likelihood to be pareto optimal and cost effective than trying to find half a trillion pounds of cash round the back of the sofa, while torching 150 years of progress so middle class people can write their book without having to have a job. If I was conspiracy minded I would say that UBI feels like a psy-op, trying to shut down old fashioned progress in favour of ripping it all out and starting again.

Ultimately, that is my real annoyance. It is far, far, far cheaper for the government to provide you with your new ramp for your house, and that is done through politics, but not fun moonshot politics, the hard shit that isn’t sexy.

#UBI#universal basic income#me being an economist on main again#the third time in twelve years#which is a pretty good record#study economics and be involved in politics#engage with the actual politics you have!#you'd be surprised how many progressive things get passed by conservative governments#and that is because you should never give up hope#I hope I don't get cancelled for my perfectly anodyne takes where I also show my working#and now back to your regularly scheduled blorbo fixating

32 notes

·

View notes

Text

Economy 101 from a sustainable business grad

Classical economics (think Adam Smith, David Ricardo, John Stuart Mill) focused on broader philosophical considerations and was much more concerned with human behavior, ethics and societal well-being. The tools used were more qualitative, based on reasoning, empirical observation and historical case studies. The main language was logic and prose. These lads were philosophers first.

Neoclassical economics, which began emerging in the late 19th century and became dominant in the 20th century, emphasized mathematical models and marginal analysis. This new approach shifted the focus toward optimization, efficiency and equilibrium in market systems. Key figures (lads like Alfred Marshall, Vilfredo Pareto and later, Milton Friedman) put more weight on mathematical models and assumptions about rational behavior (it can be questioned how rational these things are really as many are shit like "answer to everything is consumption", basically), which reduced the focus on broader ethical considerations. Philosophers were replaced by mathematicians.

The rise of neoclassical economics coincided with the mid-20th-century growth in industrial activity, particularly after WW2.

Post-WW2 marks the beginning rapid increase in CO2 emissions. There was a significant rise in industrial activity, especially in the USA, Europe and Japan, which were recovering from the war and wanted to improve their economy. Proof below.

#economy#co2 emissions#climate crisis#climate justice#climate action#climate change#climate catastrophe#economic justice#economic theory#economic development#economic growth#late stage capitalism#anti capitalism#sustainability grad#sustainability#politics#us politics#eu politics

5 notes

·

View notes

Text

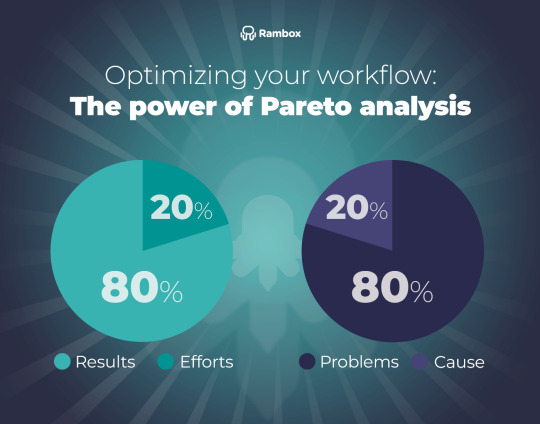

Maximizing Efficiency with Pareto Analysis

Source: https://rambox.app/wp-content/uploads/2023/10/The-power-of-Pareto-analysis.png

In the fast-paced world of business and problem-solving, prioritizing actions can make the difference between success and failure. Enter Pareto Analysis, a powerful tool rooted in the 80/20 rule, which helps identify the most significant factors affecting outcomes. This principle, named after the Italian economist Vilfredo Pareto, asserts that 80% of effects often come from 20% of causes. Here’s why and how Pareto Analysis can transform your approach to tackling challenges.

The Power of the 80/20 Rule

The 80/20 rule is both simple and profound. It suggests that a small number of causes (20%) are responsible for the majority of effects (80%). In business, this might mean that 80% of your revenue comes from 20% of your customers, or 80% of your problems stem from 20% of the underlying causes. Recognizing this disproportionate distribution allows you to focus your efforts on the areas that will yield the most significant improvements.

Implementing Pareto Analysis

Identify Key Issues: Begin by listing all the problems or causes related to the situation at hand. This could be defects in a product, customer complaints, or sources of inefficiency.

Quantify the Impact: Measure the frequency or severity of each issue. This data-driven approach ensures your analysis is based on facts, not assumptions.

Rank and Prioritize: Arrange the issues from most significant to least significant. This ranking helps in visualizing which problems are the most critical.

Create a Pareto Chart: Construct a bar graph with causes on the x-axis and their impact on the y-axis. Add a cumulative percentage line to see how quickly the issues add up to 80% of the problem.

Benefits of Pareto Analysis

Focus on What Matters: By zeroing in on the most impactful issues, you can allocate resources more effectively and achieve quicker results.

Data-Driven Decisions: Pareto Analysis removes guesswork, allowing decisions to be based on solid data.

Improved Efficiency: Addressing the key causes first leads to significant improvements with less effort.

Real-World Example

Consider a software company facing numerous customer complaints. A Pareto Analysis might reveal that 80% of complaints come from 20% of the software bugs. By prioritizing fixes for these critical bugs, the company can significantly enhance user satisfaction and reduce the volume of complaints.

Conclusion

Pareto Analysis is a game-changer for anyone looking to optimize processes and solve problems efficiently. By focusing on the vital few causes that have the greatest impact, you can make meaningful progress without being overwhelmed by the many lesser issues. Embrace the 80/20 rule and watch your efficiency and effectiveness soar.

Maximize your impact with Pareto Analysis, and turn your biggest challenges into your most significant victories.

📊✨ #ParetoAnalysis #8020Rule #Efficiency #ProblemSolving #DataDriven #BusinessStrategy #Optimize

#80/20 rule#analysis#engineering#business#education#tools#paretoprinciple#strategies#business strategy

2 notes

·

View notes

Text

Power laws, whereby a small number of people tend to be responsible for a huge proportion of any phenomenon, can be found in all human activity, whether it be income, book sales by authors, or number of sexual partners; the most well-known, the Pareto principle, or the 80/20 rule, originally comes from Italian land ownership.

Lawbreaking, too, observes a power law, so that a huge proportion of crime is committed by a very small number of offenders who have an outsized impact on society.

Inquisitive Bird wrote that power laws are ‘observed for arrests, convictions and even self-reported delinquent behavior’. He cited British data which shows that ‘70% of custodial sentences are imposed on those with at least seven previous convictions or cautions, and 50% are imposed on those with at least 15 previous convictions or cautions (Cuthbertson, 2017).

‘But perhaps the most illustrative study is by Falk et al. (2014), who used Swedish nationwide data of all 2.4 million individuals born in 1958–1980 and looked at the distribution of violent crime convictions. In short, they found that 1% of people were accountable for 63% of all violent crime convictions, and 0.12% of people accounted for 20% of violent crime convictions.’

Therefore in Sweden, some ‘70–80% of violent crimes are recidivism after an earlier conviction for a violent crime’, and ‘approximately half of violent crime convictions were committed by people who already had 3 or more violent crime convictions. In other words, if after being convicted of 3 violent crimes people were prevented from further offending, half of violent crime convictions would have been avoided.’

The author notes that, although ‘America has a reputation of a very harsh penal system that is very quick to lock anyone up’, this is not true. In fact one study found that ‘72.8% of federal offenders sentenced had been convicted of a prior offense. The average number of previous convictions was 6.1 among offenders with criminal history.’

Contrary to what received opinion in Britain believes, America is not a particularly punitive country; in fact criminals are often allowed to repeatedly offend until the inevitable tragedy happens.

The post cites analysis by the National Institute for Criminal Justice Reform which finds that ‘Overall, most victims and suspects with prior criminal offenses had been arrested about 11 times for about 13 different offenses by the time of the homicide. This count only refers to adult arrests and juvenile arrests were not included.’

In Washington DC, about 60–70% of all gun violence is carried out by just 500 individuals, and the same Pareto principle applies to shoplifting, the bane of big liberal cities like San Francisco or Vancouver, where 40 offenders were arrested 6,000 times in a year.

According to the New York Times, ‘Nearly a third of all shoplifting arrests in New York City last year involved just 327 people, the police said. Collectively, they were arrested and rearrested more than 6,000 times.’ That third is therefore committed by less than 0.004% of New York’s population.

The same is true of Britain. According to the Daily Telegraph, ‘Prolific thieves are being caught and convicted of stealing up to 50 times before they are jailed by the courts.

‘Violent offenders are escaping jail until they have been convicted of up to 25 common assaults, while some are accruing as many as seven or eight repeat convictions for carrying a knife before they are given a prison sentence. Other criminals are collecting more than 20 drug convictions before being jailed.’

The paper reported that one-tenth of offenders in England and Wales commit half of all crimes, and that ‘10,400 “super-prolific” offenders who had been convicted of more than 50 previous offences each were spared jail over the past three years’. Between 2019 and 2021, 100,000 offenders with more than 16 previous convictions avoided prison.

They also found that for theft, prolific offenders had to rack up 49 previous convictions or cautions before they were jailed, ‘For robbery – theft with force or the threat of violence – it was nine previous such offences’, and for common assault 25 such attacks.

In 2020, one burglar was only jailed after 20 convictions; one knife offender was caught seven times with weapons before going down, and another eight times. ‘Even for sexual assault, the worst offender had been convicted of five previous attacks before being jailed in 2020, and three in 2021.’ How can someone commit five sexual assaults and still not be jailed?

Yet people convicted of multiple crimes will almost certainly have committed many, many more. One study ‘followed 411 South London men from age 8–9 in the early 1960s through their lives’ and found they admitted to ‘committing many hundreds of times more crimes than they were ever caught for.’ On top of this, most burglars also routinely shoplift, and the fact that people who self-report greater numbers of crimes tend to get caught and convicted later in life ‘implies that self reports have some level of validity’.

Unsurprisingly, British criminals released after short sentences of less than 12 months are more likely than not to reoffend within a year, while only 5% of those who endure stretches of 10 years or more do so.

All of this has huge implications for crime policy and suggests that merely relying on higher clear-up rates, and the stronger possibility of detection, are not enough in themselves. [...]

What matters is that persistent wrongdoers are kept away from society.

A friend based in Singapore has on occasion sent pictures of his bike, in a rack on a main road where he leaves it overnight, unlocked. The fact that he does so, and expects to see it in the morning, is almost mind-blowing to me. [...]

But such levels of civilisation are simply impossible when a small minority of criminals are allowed to mingle freely in society. Urban honesty boxes are impossible not because British society is inherently wicked but because a relatively tiny number of people would clear them out. Imprisoning several thousand more persistent wrongdoers, for long stretches, would bring Britain’s crime rates down to similar levels enjoyed in Singapore, where shops can stay open into the small hours without security, and women can walk home late at night listening to music on their earphones.

Until policymakers accept that prolific criminals have to be incapacitated, the rest of us are condemned to a quality of life well below what we should expect.

2 notes

·

View notes

Text

Well Agnes there is a very very long answer that involves a lot of discourse analysis & historicism but the tl;dr is Mosca, Pareto, Michels, & the Italian school of elitism --> laundered into American English sociopolitical vernacular in the 50s and 60s, I'd cite C. Wright Mills' The Power Elite (1956) and G. William Domhoff's Who Rules America (1967) off the dome if we're talking trade paperbacks with popular readership, also part of why Elite Capture made me insane and I couldn't get past the intro, it didn't adequately account for the intellectual origins of ~elite theory or interrogate how "elites" often doubles as a dogwhistle

Per your question re: terminology on a purely semantic level I'd say it's because "ruler" implies sovereignty and "elite" implies a kind of soft power, plus applies to non-gov't subjects (plus the shadowy vizier vibe goes hand in hand with aforementioned dogwhistles and the conspiratorial logics they signal)

Why am I talking to Agnes's mastodon posts at 10.30 pm. Analytic philosophers please learn one (1) thing about sociology and the history of Discourses I guess lol

12 notes

·

View notes

Text

7 QUALITY CONTROL TOOLS FOR PROCESS IMPROVEMENT

“As much as 95 per cent of all quality-related problems in the factory can be solved with seven fundamental quantitative tools.”

-Kaoru Ishikawa, The inventor of Fishbone Diagram

In today’s customer-centric market, quality is an integral factor in the growth and sustainability of any business. Businesses go the extra mile to provide the best and excellent customer experience to ensure customer satisfaction. Hence, efficient quality management which has the highest impact on customer experience is one of the most essential features for any business.

Introduced by Kaoru Ishikawa, the seven basic tools of quality also known as 7QC tools are very effective in quality management and quality assurance process. So, businesses who want to ensure competitive and excellent quality of their products and services can utilize the proven 7QC tools for structuring a strategic plan for quality improvement.

LIST OF 7 QC TOOLS

Cause and Effect Diagram

Cause and Effect Diagram also known as Fishbone Diagram helps in identifying the potential causes of an effect or a problem. In addition to sorting ideas in respective categories, it also helps in understanding the areas of opportunity through effective brainstorming. Fishbone training empowers you to identify the potential cause in the problem.

Control Chart

Control charts are used to study how the processes have changed over a period of time. Further, by comparing current data to historical control limits, one could lead to the conclusion about whether the process variation is consistent as in under control or unpredictable as in out of the control due to being affected by special causes of variation.

Pareto Chart

Pareto Chart is based on the 80/20 rule where it shows the significant factors that have the highest impact on the identified problem.

Check Sheet

Check sheet is a structured process which helps to collect and analyzing data. It is an effective tool that can be for a variety of purposes.

Histogram

Histogram is commonly used a graph that shows the data and its frequency of distribution to help users identify each different value in a set of data occurs.

Scatter Diagram

Scatter diagram shows the relationship between two important factors i.e. pairs of numerical data, one variable on each axis to demonstrate the relationship.

Stratification

Stratification also known as a flow chart or run chart is a technique that separates the data gathered from a variety of sources so that patterns can be seen i.e., the path an entity has taken through a defined process.

Utilizing the 7 QC tools in six sigma or quality management process helps in taking a systematic approach to identify and understand the risk, assess the risk, control fluctuation of product quality and accordingly provide solutions to avoid future defects.

WHEN SHOULD YOU USE 7 QC TOOLS?

7 QC tools can be carried out during the quality management, quality improvement process, six sigma implementation processes or even the regular PDCA cycle for the quality purpose for enhanced quality management.

In the first phase of measuring and identifying, Fishbone Diagram also known as cause and effect diagram, Pareto Chart and Control Chart can be utilized. In the next phases of assessment and analysis, Scatter Diagram, Histogram and Checklist can be carried out. The Control Chart can be utilized consistent quality improvement.

BENEFITS OF 7 QC TOOLS

The 7 QC tools are structured and fundamental instruments that help businesses improve their management and production process for achieving enhanced product quality.

From assessing and examining the production process, identification of key challenges and problems to controlling the fluctuation present in the product quality and providing solutions for prevention of defects in future, the easy to understand and implement, 7 QC tools are very effective. Some of the major business benefits of 7 QC tools are listed below.

Provides a more structured path for problem-solving and quality improvement

Easy to understand as well as implement yet extremely effective

A scientific and logical approach for problem-solving

Follows the 80/20 rule i.e. gain 80% result with 20% efforts

Improve the quality of product and services

Helps in identifying and analyzing problems during the process

Fishbone training aides in root cause analysis and problem-solving

Encourages team spirit and fosters a healthy culture

Identifies roots cause and solve it permanently

Enhance customer experience and customer satisfaction

Based on the data-driven process and customer-centric approach, 7 QC tools implementation is one of the most effective processes that too in the shortest amount of time.

4C team of certified professionals has provided 80+ implementation of 7 QC Tools and 120+ 7 QC Tools Training. By solving 200+ quality problems, 4C has empowered clients to reduce the 80% cost of poor quality. To accelerate your quality management process and reduce your cost of poor quality, contact our experts now.

#iso certification#iso certification consultants#iso consultancy#iso consultant#iso certificate online#iso certification in india

3 notes

·

View notes

Text

Daftar istilah dan metode dalam Statistika:

1. Data

2. Variabel

3. Rata-rata (Mean)

4. Median

5. Modus

6. Standar Deviasi

7. Distribusi Normal

8. Regresi

9. Korelasi

10. Uji Hipotesis

11. Interval Kepercayaan

12. Chi-Square

13. ANOVA

14. Regresi Linier

15. Metode Maximum Likelihood (ML)

16. Bootstrap

17. Pengambilan Sampel Acak Sederhana

18. Distribusi Poisson

19. Teorema Pusat Batas

20. Pengujian Non-parametrik

21. Analisis Regresi Logistik

22. Statistik Deskriptif

23. Grafik

24. Pengambilan Sampel Berstrata

25. Pengambilan Sampel Klaster

26. Statistik Bayes

27. Statistik Inferensial

28. Statistik Parametrik

29. Statistik Non-Parametrik

30. Pengujian A/B (A/B Testing)

31. Pengujian Satu Arah dan Dua Arah

32. Validitas dan Reliabilitas

33. Peramalan (Forecasting)

34. Analisis Faktor

35. Regresi Logistik Ganda

36. Model Linier General (GLM)

37. Korelasi Kanonikal

38. Uji T

39. Uji Z

40. Uji Wilcoxon

41. Uji Mann-Whitney

42. Uji Kruskal-Wallis

43. Uji Friedman

44. Uji Chi-Square Pearson

45. Uji McNemar

46. Uji Kolmogorov-Smirnov

47. Uji Levene

48. Uji Shapiro-Wilk

49. Uji Durbin-Watson

50. Metode Kuadrat Terkecil (Least Squares Method)

51. Uji F

52. Uji t Berpasangan

53. Uji t Independen

54. Uji Chi-Square Kemerdekaan

55. Analisis Komponen Utama (PCA)

56. Analisis Diskriminan

57. Pengujian Homogenitas Varians

58. Pengujian Normalitas

59. Peta Kendali (Control Chart)

60. Grafik Pareto

61. Sampling Proporsional Terhadap Ukuran (PPS)

62. Pengambilan Sampel Multistage

63. Pengambilan Sampel Sistematis

64. Pengambilan Sampel Stratified Cluster

65. Statistik Spasial

66. Uji K-Sample Anderson-Darling

67. Statistik Bayes Empiris

68. Regresi Nonlinier

69. Regresi Logistik Ordinal

70. Estimasi Kernel

71. Pengujian Kuadrat Terkecil Penilaian Residu (LASSO)

72. Analisis Survival (Survival Analysis)

73. Regresi Cox Proportional Hazards

74. Analisis Multivariat

75. Pengujian Homogenitas

76. Pengujian Heteroskedastisitas

77. Interval Kepercayaan Bootstrap

78. Pengujian Bootstrap

79. Model ARIMA (Autoregressive Integrated Moving Average)

80. Skala Likert

81. Metode Jackknife

82. Statistik Epidemiologi

83. Statistik Genetik

84. Statistik Olahraga

85. Statistik Sosial

86. Statistik Bisnis

87. Statistik Pendidikan

88. Statistik Medis

89. Statistik Lingkungan

90. Statistik Keuangan

91. Statistik Geospasial

92. Statistik Psikologi

93. Statistik Teknik Industri

94. Statistik Pertanian

95. Statistik Perdagangan dan Ekonomi

96. Statistik Hukum

97. Statistik Politik

98. Statistik Media dan Komunikasi

99. Statistik Teknik Sipil

100. Statistik Sumber Daya Manusia

101. Regresi Logistik Binomialis

102. Uji McNemar-Bowker

103. Uji Kolmogorov-Smirnov Lilliefors

104. Uji Jarque-Bera

105. Uji Mann-Kendall

106. Uji Siegel-Tukey

107. Uji Kruskal-Wallis Tingkat Lanjut

108. Statistik Proses

109. Statistik Keandalan (Reliability)

110. Pengujian Bootstrap Berkasus Ganda

111. Pengujian Bootstrap Berkasus Baku

112. Statistik Kualitas

113. Statistik Komputasi

114. Pengujian Bootstrap Kategorikal

115. Statistik Industri

116. Metode Penghalusan (Smoothing Methods)

117. Uji White

118. Uji Breusch-Pagan

119. Uji Jarque-Bera Asimetri dan Kurtosis

120. Statistik Eksperimental

121. Statistik Multivariat Tidak Parametrik

122. Statistik Stokastik

123. Statistik Peramalan Bisnis

124. Statistik Parametrik Bayes

125. Statistik Suku Bunga

126. Statistik Tenaga Kerja

127. Analisis Jalur (Path Analysis)

128. Statistik Fuzzy

129. Statistik Ekonometrika

130. Statistik Inflasi

131. Statistik Kependudukan

132. Statistik Teknik Pertambangan

133. Statistik Kualitatif

134. Statistik Kuantitatif

135. Analisis Ragam Keterkaitan (Canonical Correlation Analysis)

136. Uji Kuadrat Terkecil Parsial (Partial Least Squares Regression)

137. Uji Haar

138. Uji Jarque-Bera Multivariat

139. Pengujian Bootstrap Berkasus Acak

140. Pengujian Bootstrap Berkasus Tak Baku

3 notes

·

View notes

Text

Continuous Improvement

The manufacturing sector is highly competitive, and companies must continually improve their processes. In this article, we will discuss a step-by-step approach to continuous improvement in manufacturing. We will focus on collecting data for the process, prioritizing problems, monitoring defects, identifying the root cause of defects, standardizing the fix, and confirming the solution’s…

View On WordPress

#Continuous improvement#control chart#Cost reduction#data collection#defect monitoring#first-time yield#manufacturing#Pareto analysis#problem prioritization#productivity#Quality#Root Cause analysis#Standardization

0 notes

Text

How Can ISO 9001 Certification Consultants Help Reduce Resource Waste?

What is resource waste? In the simplest terms, it is the unnecessary use of resources. This leads to a higher amount of depletion. This term applies to a variety of settings, including business operations, manufacturing, agriculture, and everyday activities. Resources can include materials, time, energy, money, or human effort. Budget constraints and lack of quality controls are two pivotal issues associated with resource waste. If quality is not met, a company is unable to maintain sustainability. Customer satisfaction is directly linked to quality management. To ensure you maintain brand awareness and a competitive advantage, an ISO certification for quality assurance is essential. ISO 9001 certification consultants are experienced professionals who can help with the improvement processed needed within your current quality management system. You can rectify any quality management-related issues while at the same time achieve 100% regulatory compliance.

Since these consultants are committed to enhancing the quality of your services/products, they will focus strongly on reducing resource wastage. These professionals believe in increasing resource efficiency by prioritizing their values. In this way, the lifecycle of all resources is analyzed. Through this process, they will help your management team and stakeholders mobilize resources in a much more effective way.

How do ISO 9001 certification consultants reduce resource wastage?

Process Optimization - Consultants help organizations map their workflows to identify inefficiencies, redundancies, or bottlenecks. They develop and implement standardized operating procedures (SOPs) that minimize errors and reduce resource waste. By incorporating lean methodologies, they eliminate non-value-adding activities, reduce waste of time and materials.

Waste Management

Defect Reduction: By focusing on quality at every production stage, consultants help reduce defects and rework, directly cutting material wastage.

Efficient Resource Allocation: They identify underutilized or overused resources and recommend balancing measures.

3. Improved Monitoring and Measurement

Data-Driven Decisions: Consultants implement robust monitoring systems to measure key performance indicators (KPIs), helping businesses track and reduce waste.

Root Cause Analysis: They use tools like fishbone diagrams and Pareto analysis to address recurring issues that lead to waste.

4. Employee Training and Awareness

Skill Development: Training employees in quality management systems (QMS) ensures they understand how to use resources effectively.

Awareness Programs: Creating awareness about the cost and impact of waste fosters a culture of responsibility.

5. Supplier and Material Management

Supplier Evaluation: Consultants help select suppliers with consistent quality standards, reducing issues caused by subpar raw materials.

Inventory Management: They recommend just-in-time practices to avoid overstocking, spoilage, or obsolescence of materials.

Continuous Improvement Culture

Plan-Do-Check-Act (PDCA): Consultants introduce the PDCA cycle for ongoing improvements to reduce waste.

Feedback Loops: Regular reviews and feedback mechanisms ensure that waste reduction initiatives are sustained.

When you hire an experienced ISO 9001 certification consultants for the first time, contact several reputable agencies. Dig into their background information and verify their certification in quality management and audit. To minimize waste, you need professionals who have a minimum of ten years of expertise in a relevant industry. Have a face-to-face appointment prior to selecting a team or an expert.

Also Read: Learn from Experts About the Five Requirements of The ISO 17025?

0 notes

Text

Master Quality Control with 7QC Tools Training by 4C Consulting

In the competitive world of manufacturing and production, maintaining high quality standards is crucial for success. The 7QC Tools Training offered by 4C Consulting equips professionals with essential tools for effective quality control and process improvement. This blog provides a comprehensive overview of the 7QC Tools, their importance, and how the training can benefit organizations in achieving superior quality management.

Understanding 7QC Tools

Definition: The 7QC Tools (Seven Quality Control Tools) are fundamental instruments used in quality management and problem-solving processes. These tools are widely recognized for their simplicity, effectiveness, and ability to aid in data analysis and decision-making.

The Seven Tools:

Cause-and-Effect Diagram (Fishbone/Ishikawa Diagram): Identifies potential causes of a problem to find the root cause.

Check Sheet: A structured, prepared form for collecting and analyzing data.

Control Chart: Monitors process variation and stability over time.

Histogram: Graphically displays the distribution of data.

Pareto Chart: Highlights the most significant factors in a data set.

Scatter Diagram: Analyzes the relationship between two variables.

Flow Chart (Process Mapping): Visualizes the steps in a process.

Importance of 7QC Tools

Problem Identification and Resolution: Helps in identifying the root causes of quality issues and developing effective solutions.

Data-Driven Decisions: Provides a basis for making decisions based on actual data rather than assumptions.

Process Improvement: Facilitates continuous improvement in processes, leading to higher efficiency and reduced waste.

Enhanced Product Quality: Ensures that products meet or exceed customer expectations by controlling and improving quality.

Employee Engagement: Involves employees in quality control processes, fostering a culture of quality and accountability.

Customer Satisfaction: Leads to higher customer satisfaction by consistently delivering high-quality products and services.

7QC Tools Training

Understanding 7QC Tools:

Cause-and-Effect Diagram: Learn to create and analyze fishbone diagrams to identify root causes of problems.

Check Sheet: Understand the design and use of check sheets for data collection and analysis.

Control Chart: Gain skills in developing and interpreting control charts to monitor process variation.

Histogram: Learn to construct histograms and analyze data distribution patterns.

Pareto Chart: Understand the 80/20 rule and how to apply it using Pareto charts.

Scatter Diagram: Develop skills in plotting and interpreting scatter diagrams to identify relationships between variables.

Flow Chart: Learn to create process maps to visualize and improve workflows.

Importance of Training:

Practical Skills: Provides hands-on experience in using each of the 7QC tools effectively.

Analytical Thinking: Enhances analytical and critical thinking skills required for quality management.

Improvement Projects: Equips participants with the knowledge to lead and participate in process improvement projects.

Certification: Validates the skills and knowledge acquired, adding value to professional credentials.

Why Choose 4C Consulting?

4C Consulting offers comprehensive 7QC Tools Training designed to empower professionals with the knowledge and skills needed for effective quality control. Our expert trainers bring extensive industry experience, ensuring practical and relevant learning. We provide customized training solutions tailored to meet the specific needs of your organization, fostering a culture of continuous improvement. By choosing 4C Consulting, you gain access to the best practices in quality management, helping your organization achieve excellence in product quality and customer satisfaction. Contact us now.

0 notes

Text

I asked chatGPT, “when did math enter into economics” and the following was generated:

Mathematics began entering economics gradually, gaining prominence in different phases of the discipline’s evolution. Here’s a timeline highlighting key moments:

Pre-18th Century: Early Use of Math in Economics

1. Mercantilism and Arithmetic:

• During the mercantilist period (16th–17th centuries), arithmetic was used in trade and national accounting, focusing on balancing trade flows and calculating tariffs.

2. William Petty (17th Century):

• William Petty, a political economist and statistician, used early mathematical techniques in the 1600s to estimate population, national income, and economic productivity. He is sometimes credited as a precursor to modern econometrics.

18th Century: Limited Mathematical Application

1. Adam Smith and the Classical School:

• Adam Smith (The Wealth of Nations, 1776) and other early classical economists largely avoided formal mathematics, relying instead on verbal reasoning and logic.

• While Smith referenced arithmetic and proportionality to explain concepts like the division of labor, his work remained qualitative.

19th Century: Emergence of Mathematical Economics

1. David Ricardo and Algebraic Reasoning:

• Ricardo used rudimentary algebraic techniques in his models, particularly regarding comparative advantage and rent theory.

• His work hinted at a quantitative approach but was not heavily formalized.

2. Cournot (1838):

• Augustin Cournot’s Researches into the Mathematical Principles of the Theory of Wealth (1838) is considered a milestone in the formalization of economics.

• He introduced calculus to model monopolies, duopolies, and supply-demand dynamics, emphasizing marginal analysis.

3. Jevons and the Marginal Revolution (1870s):

• William Stanley Jevons, Léon Walras, and Carl Menger independently developed marginal utility theory.

• Jevons and Walras incorporated calculus and mathematical optimization into economic theory, formalizing the relationship between utility, prices, and quantities.

Late 19th to Early 20th Century: Mathematics Grows in Influence

1. Alfred Marshall (1890):

• Alfred Marshall’s Principles of Economics formalized supply and demand analysis and introduced mathematical diagrams, such as the supply-demand curve.

• Marshall advocated using mathematics as a “short-hand language,” but he believed economic arguments should be explained in words.

2. Pareto and General Equilibrium (1900s):

• Vilfredo Pareto expanded Walras’s general equilibrium theory using mathematical rigor, introducing concepts like Pareto efficiency.

3. Statistics and Econometrics:

• By the early 20th century, statistical methods entered economics, driven by advances in data collection and analysis (e.g., national income accounts).

Mid-20th Century: Full Integration of Mathematics

1. Keynesian Economics and Formal Models (1930s–40s):

• John Maynard Keynes’s General Theory of Employment, Interest, and Money (1936) inspired mathematical formalization of macroeconomics, particularly in IS-LM models (Hicks-Hansen).

2. Econometrics and Linear Programming (1940s–50s):

• The Cowles Commission advanced econometrics, combining statistical techniques with economic theory.

• Paul Samuelson’s Foundations of Economic Analysis (1947) solidified the use of calculus and linear algebra as essential tools for economic modeling.

3. Game Theory (1944):

• John von Neumann and Oskar Morgenstern’s Theory of Games and Economic Behavior introduced game theory, adding a new mathematical dimension to economics.

Modern Era (Late 20th Century Onward):

1. Computational Economics:

• Advances in computing allowed economists to use complex mathematical models and simulations to analyze markets and policy.

2. Behavioral Economics:

• While still grounded in mathematics, behavioral economics began integrating psychology to address limitations of purely mathematical models.

3. Data-Driven Analysis:

• The explosion of big data and machine learning in the 21st century has introduced advanced statistical and computational methods into economics.

In summary, while economics began with qualitative reasoning, mathematics started entering the field seriously in the 19th century with figures like Cournot, Jevons, and Walras. By the mid-20th century, mathematics became a core component of economics, revolutionizing its methodology and enabling rigorous, quantitative analysis of complex systems.

0 notes

Text

Synthetic Biology Market Outlook On Rising Application, Revolutionary Trends & Potential Growth Ways 2032

According to the research report, the global synthetic biology market was valued at USD 15.47 billion in 2023 and is expected to reach USD 71.51 billion by 2032, to grow at a CAGR of 18.6%during the forecast period.

Our newly published research report titled Synthetic Biology Market Insights offers a comprehensive analysis of the rapidly growing market. It highlights all the key factors anticipated to drive growth while shedding light on potential challenges and opportunities that could emerge in the market in the upcoming years. The market assessment includes a thorough analysis of Synthetic Biology market share, size, gross margin, and CAGR. The research report has been prepared using industry-standard methodologies to offer a thorough assessment of the major market participants and their market scope.

All the data and information provided in the study are curated and verified by expert analysts to provide a reliable and accurate market analysis. Also, pictorial representations such as tables, charts, and graphs have been used to enhance decision making and improve business strategy. The research report is a must-read for anyone involved or interested in the market in any form.

Key Report Features:

Comprehensive Market Data: Provides a thorough market examination of annual sales, current market size, and anticipated Synthetic Biology market growth rate during the forecast period.

Regional Analysis: Thorough analysis of all the major regions and sub-regions in the market.

Company Profiles: An in-depth assessment of all the leading market participants and emerging businesses.

Customization: Report customization as per your requirements with respect to countries, regions, and segmentation.

Major Market Participants:

The research report includes a comprehensive competitive landscape section that helps businesses understand their competitors and the market in which they operate. All the major Synthetic Biology market players have been covered in the report. By going through the competitive landscape, businesses can identify their competitors and understand their strengths and weaknesses. Also, businesses can better examine the products/services of their competitors and evaluate their offers and pricing. All the major competitive analysis frameworks, including SWOT analysis and PESTEL analysis, have been included in the research study to offer a thorough assessment of the market’s competitive scenario. Here are a few of the key players operating in the market:

Browse Full Insights

The top players operating in the market are:

Biosciences Inc.

Codexis Inc.

Creative Biogene

CREATIVE ENZYMES

Enbiotix Inc.

Illumina Inc.

Merck Kgaa (Sigma-Aldrich Co. LLC)

New England Biolabs

Euro fins Scientific

Novozymes

Pareto Bio Inc.

Market Dynamics:

Growth Drivers: The research report sheds light on all the major factors driving the robust growth of the market. Also, all the key trends and opportunities anticipated to have a favorable impact on market Synthetic Biology development have been covered in the study.

Technological Advancements: All the major advances in technology that can support market growth have been covered in the research report. Besides, the introduction of new products/services by major participants has been detailed.

Regulatory Policies: The research report examines the regulatory landscape of the constantly evolving market, shedding light on new market frameworks and policies projected to drive the market forward.

Segmental Overview:

This section of the research report categorizes the market into various segments, such as end use, product type, application, and region. Also, a thorough analysis of all the major sub-segments has been provided in the study. By going through the segmental analysis section, businesses and stakeholders can easily examine different Synthetic Biology market segments and identify consumer requirements within each of them. Besides, businesses can optimize their brand positioning and tailor their marketing efforts to specific segments. What’s more, companies can use market segmentation to identify gaps in their offerings that can developed up on.

Report Answers Questions Such As:

• What is the current market size and projected value? • What are the major factors driving Synthetic Biology market sales and demand? • What are the key developments and trends driving the market forward? • What are the key outcomes of the PESTEL analysis for the market? • Who are the major players offering their products/services in the market? • What are the major opportunities that market participants can capitalize on?

Report Summary:

The Synthetic Biology market research report is a reliable resource to understand the dynamic nature of the market. It covers several key market features, including capacity, revenue, price, consumption, production rate, and supply demand, to provide an in-depth market analysis. By going through the research study, readers can get a precise and reliable analysis of the rapidly evolving market.

More Trending Latest Reports By Polaris Market Research:

Electric Vehicles Battery Recycling Market

Jars Market

Smart Home Automation Market

Protein A, G, and L Resins Market

Automated Waste Collection Systems Market

3D Machine Vision Market

Cashmere Clothing Market

Gunshot Detection System Market

0 notes